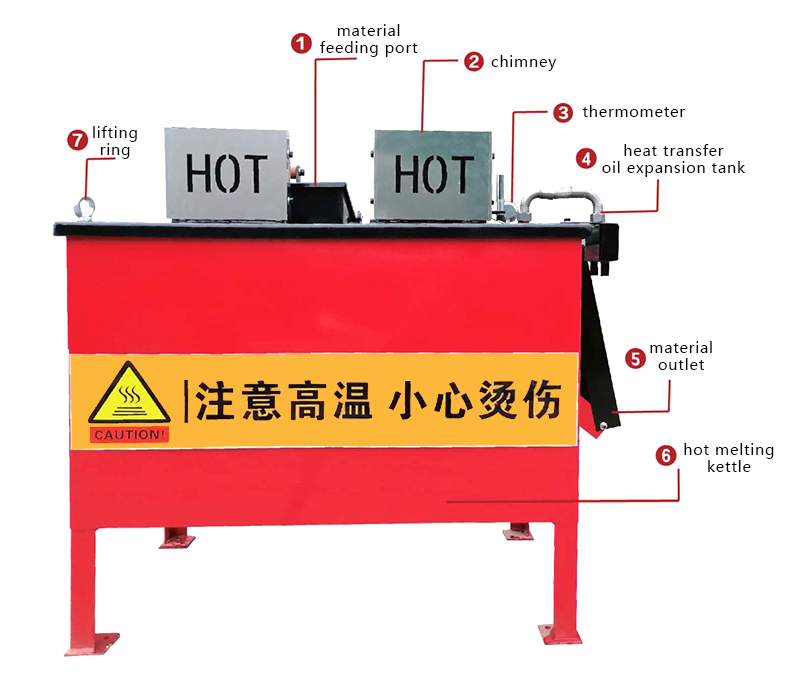

ZF42 Pavement hot melting kettle

- Brief Introduction:

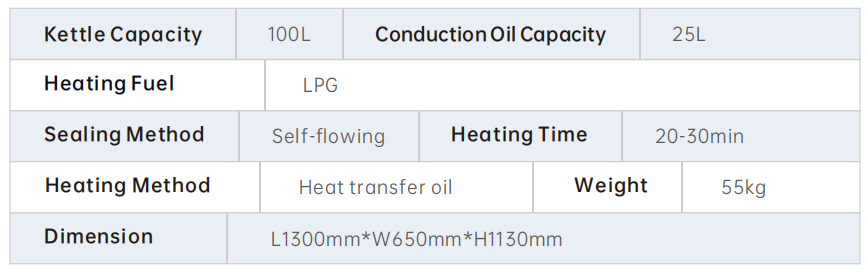

- Kettle Capacity:100L

- Heating Fuel:LPG

- Conduction Oil Capacity:25L

- Heating Time:20-30m/min

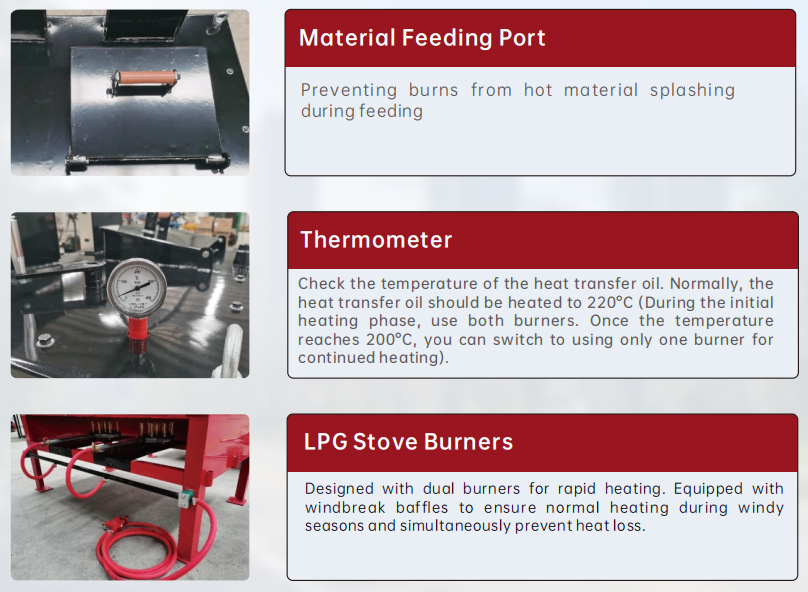

Anti splash design can protect workers from being scalded by hot material splashing during feeding. Check the temperature of the heat transfer oil. Normally, the heat transfer oil should be heated to 220 degrees (when heating for the first time, turn on two burners, and when the temperature reaches 200 degrees, only one burner can be used for heating). Adopting a dual stove design, the heating speed is fast and the well is equipped with a windproof baffle, ensuring that the equipment can be heated normally in windy seasons while preventing heat loss.

Product Introduction

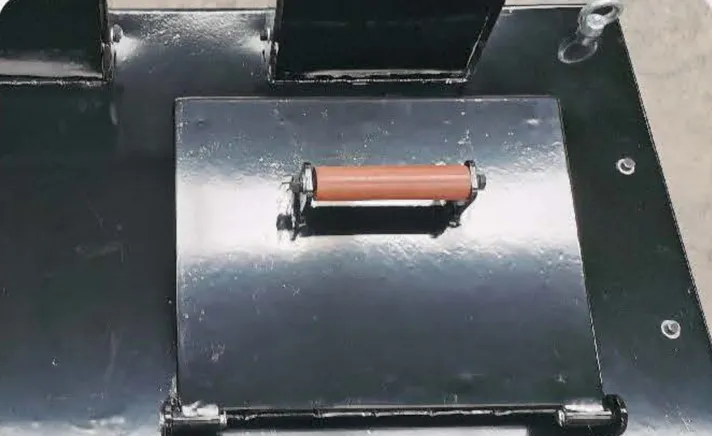

Splash-proofdesign

Preventing burns from hot material splashing during feeding.

Dual burner

For rapid heating with adjustable settings

Visible thermometer

For real-time viewing of heat transfer oiltemperature.

Windbreak baffle

To withstand windy weatherand prevent heat loss

Technical Parameters

Product Features

-

FAST MELTING, CONTINUOUS OPERATION

Continuous material feeding uninterrupted operation

-

MATERIAL FEEDING PORT

Splash-proof design toprotect workers

-

THERMOMETER

Heat the heat transfer oil to 220°c,(During the first heating, turn on both burnersOnce the temperature reaches 200'C,you canuse only one burner for heating.)

Our Factory VR

Application scenarios

-

Hospital

-

Supermarket

-

Mall

-

Airport